Factory Direct Sales of Gears and Sprockets

1, Core positioning

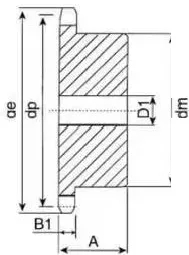

Stainless steel sprocket is a core component of power transmission made of stainless steel material, which precisely meshes with roller chains. It is designed for harsh working conditions such as humidity, salt spray, acid and alkali corrosion, and high hygiene requirements. It is compatible with standard/non-standard chains, with smooth transmission, long service life, and low maintenance costs.

2, Core advantages

• Super corrosion resistance: The surface chromium oxide film isolates corrosive media, and the corrosion resistance of 304/316L chain wheels is 3-5 times higher than that of carbon steel chain wheels. The service life is extended by 2-3 times in humid/salt spray/acid-base environments.

• Hygiene and Cleanliness: Non toxic, non precipitating, easy to rinse, suitable for clean environments such as food and pharmaceuticals, and meets hygiene standards.

High strength and wear-resistant: The tooth surface can be quenched/carburized to HRC45-50, which is wear-resistant and deformation resistant; 316L is also resistant to high temperatures (≤ 400 ºC) and chloride ion corrosion.

• Strong adaptability: single row/double row/multi row, support standard (such as 08A/10A/12A) and non-standard customization, and meet different transmission ratios and installation requirements.