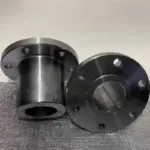

Rigid Flange Coupling with Keyway for Tractor Pto

Flange Coupling – Reliable Rigid Connection for Agricultural Machinery

Our flange coupling is engineered to provide a secure, high‑torque connection for a wide range of agricultural equipment. Its rigid, zero‑backlash design ensures precise power transmission, making it ideal for tractors, combines, harvesters, and other heavy‑duty farm machinery.

Constructed from durable carbon steel with heat‑treated surfaces, this coupling delivers excellent strength, wear resistance, and durability in dusty, high‑vibration environments. The compact flange structure allows for easy installation and accurate alignment, reducing maintenance time and improving overall system reliability.

With customizable bore sizes, keyways, and mounting configurations, our flange coupling can be tailored to fit various PTO systems, hydraulic pumps, gearboxes, and drive shafts. It is widely used in applications requiring stable, continuous power transfer, including tractor front‑end loaders, combine harvester drives, and sprayer pump systems.

Product parameters

| Flange Coupling Size Table (mm) | ||||||||||

| outside diameter | inside diameter | height | keyway | Connection hole diameter | screw | Connection hole center distance | Number of connection holes | step diameter | Concave convex edge diameter | |

| 120 | 18-22 | 55 | 6 | 14 | M12 | 95 | 4 | 70 | 60 | |

| 120 | 24-30 | 55 | 8 | 14 | M12 | 95 | 4 | 70 | 60 | |

| 120 | 32-38 | 55 | 10 | 14 | M12 | 95 | 4 | 70 | 60 | |

| 120 | 40-42 | 55 | 12 | 14 | M12 | 95 | 4 | 70 | 60 | |

| 120 | 45 | 55 | 14 | 14 | M12 | 95 | 4 | 70 | 60 | |

| 150 | 28-30 | 75 | 8 | 15 | M12/M14 | 110 | 5 | 87 | 85 | |

| 150 | 32-38 | 75 | 10 | 15 | M12/M14 | 110 | 5 | 87 | 85 | |

| 150 | 40-42 | 75 | 12 | 15 | M12/M14 | 110 | 5 | 87 | 85 | |

| 150 | 45-50 | 75 | 14 | 15 | M12/M14 | 110 | 5 | 87 | 85 | |

| 150 | 55 | 75 | 16/18 | 15 | M12/M14 | 110 | 5 | 87 | 85 | |

| 150 | 60 | 75 | 18 | 15 | M12/M14 | 110 | 5 | 87 | 85 | |

| 190 | 38 | 105 | 10 | 16 | M14 | 163 | 6 | 116 | 119 | |

| 190 | 40-42 | 105 | 12 | 16 | M14 | 163 | 6 | 116 | 119 | |

| 190 | 45-50 | 105 | 14 | 16 | M14 | 163 | 6 | 116 | 119 | |

| 190 | 55 | 105 | 16 | 16 | M14 | 163 | 6 | 116 | 119 | |

| 190 | 60-65 | 105 | 18 | 16 | M14 | 163 | 6 | 116 | 119 | |

| 190 | 70-75 | 105 | 20 | 16 | M14 | 163 | 6 | 120 | 119 | |

| 190 | 80-85 | 105 | 22 | 16 | M14 | 163 | 6 | 120 | 119 | |

| 190 | 90 | 105 | 25 | 16 | M14 | 163 | 6 | 120 | 119 | |

| 240 | 60-65 | 135 | 18 | 18 | M16 | 200 | 12 | 120 | 160 | |

| 240 | 70-75 | 135 | 20 | 18 | M16 | 200 | 12 | 135 | 160 | |

| 240 | 80-90 | 135 | 22 | 18 | M16 | 200 | 12 | 165 | 160 | |

| 240 | 95-110 | 135 | 25 | 18 | M16 | 200 | 12 | 165 | 160 | |